|

Shanghai Royal Machinery Co.,LtdAir compressors, air dryer, tank , line filters and other related compressed air machine supplier |

|

||||||

High Quality Industrial Oil Free Screw Air Blower for Sewage Treatment

General parameters of our screw blower:

Pressure: 0.4-1.2bar

Air flow: 3m3/min-72m3/min

Power: 5.5kw-185kw

What is a screw blower?

Blower type

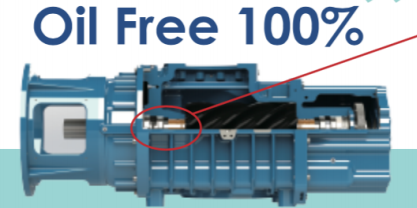

Rotary screw blowers are positive displacement blowers with precision timing gears that maintain minute clearances between two intermeshing oil-free screw elements that never touch. ... In centrifugal blowers, also called turbo blowers, the energy is transferred from a rotating shaft to air or gas.

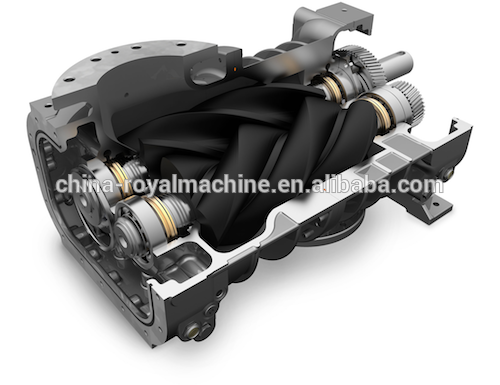

Hitachi Technology Oil free Screw blower head:

What is the difference between a Roots blower and a screw blower?

The roots blower acts like a pump for the air as it goes into the motor, whereas thescrew blower is more like an air compressor in how it forces the atmosphere into the engine. ... The rotors on the screw blower are much different since they're designed to be more like the threads on a screw, hence the name screw blower.

What are the advantages of a screw compressor?

They are good energy conservers – Rotary screw machines are generally energy efficient, and they generate less heat than normal air compressors. They consume less oil than other oil flooded air compressors. In addition, they have minimum oil carryovers.

What is a screw compressor used for?

Rotary-screw compressors are generally used to supply compressed air for larger industrial applications. They are best applied in applications that have a continuous airdemand such as food packaging plants and automated manufacturing systems.

Wastewater treatment

?Lowest aeration blower energy cost, representing 70% of the total operational cost.

Low downtime and low maintenance cost thanks to innovative screw blower technology.

Very wide fow and pressure operational range

Pneumatic conveying – dilute phase

Lowest energy cost, representing up to 80% of the blower life cycle cost.

Low downtime and low maintenance cost thanks to innovative screw blower technology.

Fermentation

• Lowest energy cost, representing up to 80% of the blower

life cycle cost.

• Low downtime and low maintenance cost thanks

to innovative screw blower technology.

• Very wide flow and pressure operational range.

Non-woven textile

• Adjustable flow in order to influence fiber characteristics.

• Energy-efficient blowers to come to the lowest

operational cost of this 24/7 continuous process.

• Point-of-use installation without

noise-preventing measures.

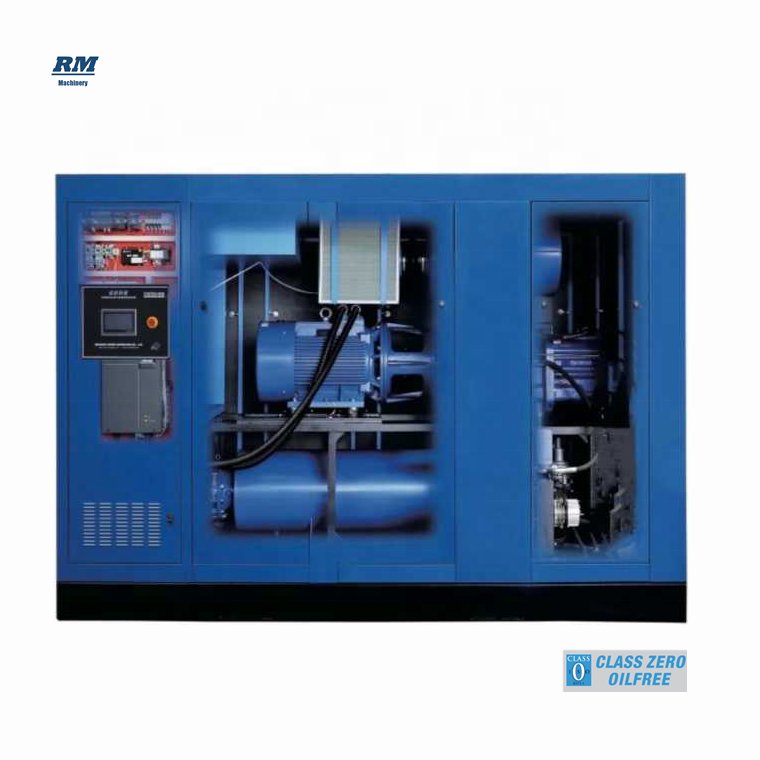

Small belt driven:

Main parameters of our screw blower:

| Model No. | Discharge Pressure | 0.4bar | 0.5bar | 0.6bar | 0.7bar | 0.8bar | 0.9bar | 1bar | 1.1bar | 1.2bar |

| RM100-5.5 | Air flow(m3/h) | 253 | 249 | 248 | 246 | 244 | 243 | 241 | 240 | 239 |

| Motor power(kw) | 5.5 | 7.5 | 7.5 | 7.5 | 7.5 | 11 | 11 | 11 | 11 | |

| RM100-5.5VSD | Air flow(m3/h) | 287 | 283 | 281 | 278 | 276 | 275 | 273 | 272 | 271 |

| Motor power(kw) | 5.5 | 7.5 | 7.5 | 11 | 11 | 11 | 11 | 11 | 15 | |

| RM100-7.5 | Air flow(m3/h) | 335 | 330 | 328 | 325 | 322 | 321 | 319 | 317 | 316 |

| Motor power(kw) | 7.5 | 7.5 | 11 | 11 | 11 | 11 | 15 | 15 | 15 | |

| RM100-7.5VSD | Air flow(m3/h) | 372 | 366 | 364 | 361 | 358 | 357 | 354 | 352 | 351 |

| Motor power(kw) | 7.5 | 7.5 | 11 | 11 | 11 | 15 | 15 | 15 | 15 | |

| GF160-11 | Air flow(m3/h) | 570 | 566 | 565 | 563 | 560 | 559 | 557 | 556 | 555 |

| Motor power(kw) | 11 | 15 | 15 | 15 | 18.5 | 18.5 | 18.5 | 22 | 22 | |

| GF160-11VSD | Air flow(m3/h) | 664 | 659 | 657 | 655 | 652 | 651 | 649 | 647 | 646 |

| Motor power(kw) | 11 | 15 | 15 | 18.5 | 18.5 | 22 | 22 | 22 | 30 | |

| GF160-15 | Air flow(m3/h) | 770 | 765 | 762 | 760 | 756 | 755 | 752 | 750 | 749 |

| Motor power(kw) | 15 | 15 | 18.5 | 18.5 | 22 | 22 | 30 | 30 | 30 | |

| GF160-15VSD | Air flow(m3/h) | 880 | 874 | 871 | 868 | 864 | 863 | 860 | 857 | 856 |

| Motor power(kw) | 15 | 18.5 | 18.5 | 22 | 22 | 30 | 30 | 30 | 30 | |

| GF160-18.5 | Air flow(m3/h) | 1111 | 1103 | 1100 | 1096 | 1090 | 1090 | 1085 | 1082 | 1080 |

| Motor power(kw) | 18.5 | 22 | 30 | 30 | 30 | 30 | 37 | 37 | 37 | |

| GF160-122 | Air flow(m3/h) | 1282 | 1273 | 1269 | 1264 | 1258 | 1258 | 1252 | 1249 | 1247 |

| Motor power(kw) | 22 | 30 | 30 | 30 | 37 | 37 | 37 | 45 | 45 | |

| GF160-22VSD | Air flow(m3/h) | 1456 | 1446 | 1442 | 1436 | 1429 | 1428 | 1423 | 1418 | 1416 |

| Motor power(kw) | 22 | 30 | 30 | 37 | 37 | 45 | 45 | 45 | 55 |

| Model No. | Discharge Pressure | 0.4bar | 0.5bar | 0.6bar | 0.7bar | 0.8bar | 0.9bar | 1bar | 1.1bar | 1.2bar |

| RM200l-22 | Air flow(m3/h) | 1226 | 1220 | 1214 | 1206 | 1199 | 1191 | 1182 | 1173 | 1163 |

| Motor power(kw) | 22 | 30 | 30 | 30 | 37 | 37 | 45 | 45 | 45 | |

| RM200l-22VSD | Air flow(m3/h) | 1386 | 1392 | 1385 | 1378 | 1370 | 1362 | 1353 | 1345 | 1336 |

| Motor power(kw) | 22 | 30 | 30 | 37 | 37 | 45 | 45 | 45 | 55 | |

| RM200l-30 | Air flow(m3/h) | 1637 | 1630.7 | 1623.3 | 1614.9 | 1606.5 | 1597.1 | 1586.6 | 1575 | 1616 |

| Motor power(kw) | 30 | 30 | 37 | 37 | 45 | 45 | 55 | 55 | 55 | |

| RM200l-30VSD | Air flow(m3/h) | 1868 | 1861 | 1853 | 1845 | 1836 | 1827 | 1818 | 1808 | 1798 |

| Motor power(kw) | 30 | 37 | 45 | 45 | 55 | 55 | 55 | 75 | 75 | |

| RM200l-37 | Air flow(m3/h) | 2104 | 2098 | 2091 | 2081 | 2071 | 2059 | 2048 | 2035 | 2022 |

| Motor power(kw) | 37 | 45 | 45 | 55 | 55 | 55 | 75 | 75 | 75 | |

| RM200l-37VSD | Air flow(m3/h) | 2435 | 2427 | 2417 | 2407 | 2395 | 2382 | 2369 | 2354 | 2339 |

| Motor power(kw) | 37 | 45 | 55 | 55 | 75 | 75 | 75 | 75 | 90 | |

| RM200l-45 | Air flow(m3/h) | 2728 | 2721 | 2711 | 2701 | 2689 | 2676 | 2663 | 2648 | 2633 |

| Motor power(kw) | 45 | 55 | 55 | 75 | 75 | 75 | 90 | 90 | 90 | |

| RM200l-45VSD | Air flow(m3/h) | 2923 | 2915 | 2905 | 2895 | 2882 | 2869 | 2855 | 2840 | 2825 |

| Motor power(kw) | 45 | 55 | 75 | 75 | 75 | 75 | 90 | 90 | 90 | |

| RM200l-55 | Air flow(m3/h) | 2975 | 2964 | 2955 | 2945 | 2936 | 2927 | 2920 | 2912 | 2901 |

| Motor power(kw) | 55 | 75 | 75 | 75 | 75 | 90 | 90 | 90 | 110 | |

| RM200l-55VSD | Air flow(m3/h) | 3418 | 3407 | 3398 | 3388 | 3379 | 3371 | 3362 | 3355 | 3347 |

| Motor power(kw) | 55 | 75 | 75 | 90 | 90 | 110 | 110 | 110 | 110 | |

| RM200l-75 | Air flow(m3/h) | 3927 | 3915 | 3905 | 3896 | 3887 | 3880 | 3871 | 3864 | 3856 |

| Motor power(kw) | 75 | 75 | 90 | 90 | 110 | 110 | 110 | 132 | 132 | |

| RM200l-75VSD | Air flow(m3/h) | 4495 | 4481 | 4469 | 4454 | 4442 | 4431 | 4422 | 4413 | 4405 |

| Motor power(kw) | 75 | 90 | 90 | 110 | 110 | 132 | 132 | 132 | 160 | |

| RM200l-90 | Air flow(m3/h) | 5041 | 5028 | 5017 | 5005 | 4995 | 4983 | 4970 | 4956 | 4948 |

| Motor power(kw) | 90 | 110 | 110 | 110 | 132 | 132 | 160 | 160 | 160 | |

| RM200l-90VSD | Air flow(m3/h) | 5651 | 5640 | 5627 | 5614 | 5603 | 5590 | 5577 | 5563 | 5551 |

| Motor power(kw) | 90 | 110 | 132 | 132 | 132 | 160 | 160 | 160 | 185 | |

| RM200l-110 | Air flow(m3/h) | 6098 | 6085 | 6072 | 6060 | 6047 | 6036 | 6028 | 6020 | 6012 |

| Motor power(kw) | 110 | 110 | 132 | 132 | 160 | 160 | 185 | 185 | 185 |

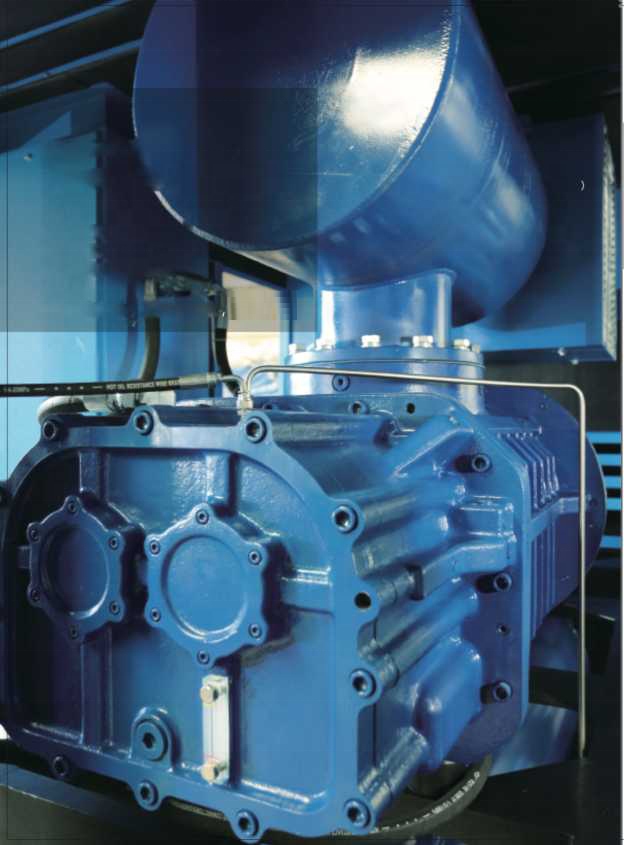

Direct driven:

Energy saving compared to Roots blower:

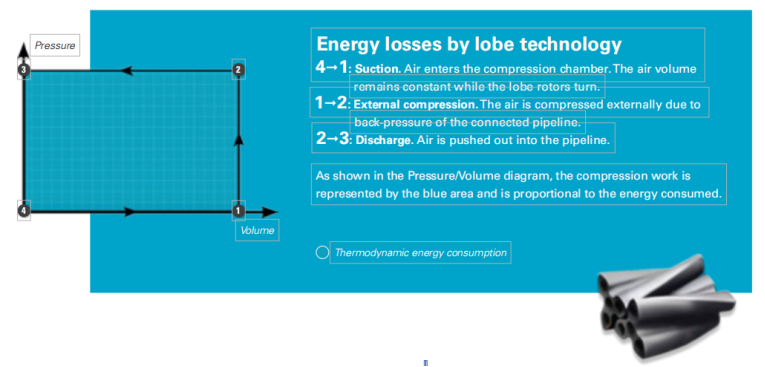

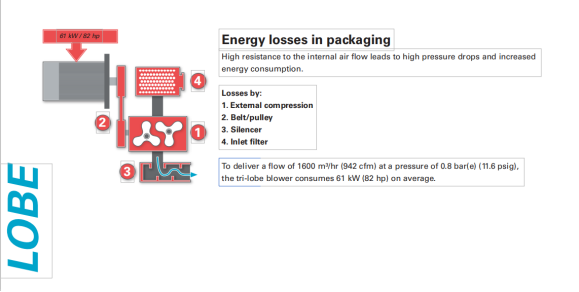

Roots blower:

To deliver a flow of 1600 m³/hr (942 cfm) at a pressure of 0.8 bar(e) (11.6 psig),

the tri-lobe blower consumes 61 kW (82 hp) on average

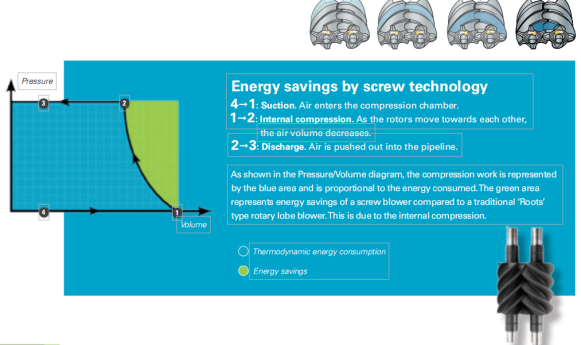

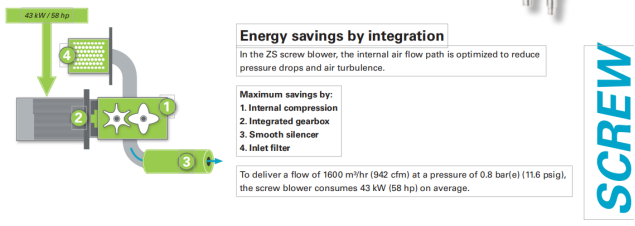

Oil free screw blower:

To deliver a flow of 1600 m³/hr (942 cfm) at a pressure of 0.8 bar(e) (11.6 psig),

the screw blower consumes 43 kW (58 hp) on average.

Welcome to contact with us for more information.

2.5bar-3.5bar screw air compressors:

| Model No. | Power | Pressure | Air capacity | Outlet connect | Weight | Dimension(mm) | |||

| kw | hp | Mpa | m3/min | kg | L | W | H | ||

| RM-30L/A | 22 | 30 | 0.25 | 6.9 | DN50 | 950 | 1350 | 1220 | 1460 |

| 0.35 | 5.3 | ||||||||

| RM-50L/A | 37 | 50 | 0.25 | 12.6 | DN65 | 1500 | 1900 | 1400 | 1630 |

| 0.35 | 9.5 | ||||||||

| RM-60L/A | 45 | 60 | 0.25 | 16 | DN65 | 1850 | 1900 | 1400 | 1630 |

| 0.35 | 13.5 | ||||||||

| RM-75L/A | 55 | 75 | 0.25 | 21.2 | DN80 | 2100 | 2100 | 1400 | 1750 |

| 0.35 | 16.8 | ||||||||

| RM-100L/A | 75 | 100 | 0.25 | 26.6 | DN80 | 2500 | 2860 | 1640 | 1860 |

| 0.35 | 21.2 | ||||||||

| RM-125L/A | 90 | 125 | 0.25 | 30.8 | DN100 | 2800 | 2860 | 1640 | 1860 |

| 0.35 | 25.5 | ||||||||

| RM-150L/A | 110 | 150 | 0.25 | 39.6 | DN100 | 3500 | 2860 | 1640 | 1860 |

| 0.35 | 31.8 | ||||||||

| RM-175L/A | 132 | 175 | 0.25 | 46 | DN125 | 3700 | 3240 | 2000 | 2150 |

| 0.35 | 40.2 | ||||||||

| RM-220L/A | 160 | 220 | 0.25 | 53 | DN125 | 4800 | 3240 | 2000 | 2150 |

| 0.35 | 46.8 | ||||||||

| RM-250L/W | 185 | 250 | 0.25 | 55.6 | DN150 | 5300 | 3240 | 2000 | 2150 |

| 0.35 | 51.6 | ||||||||

| RM-270L/W | 200 | 270 | 0.25 | 60.1 | DN150 | 5500 | 3240 | 2000 | 2150 |

| 0.35 | 55.7 | ||||||||

| RM-300L/W | 220 | 300 | 0.25 | 66.1 | DN150 | 6500 | 3240 | 2000 | 2150 |

| 0.35 | 61.3 | ||||||||