|

Shanghai Royal Machinery Co.,LtdAir compressors, air dryer, tank , line filters and other related compressed air machine supplier |

|

||||||

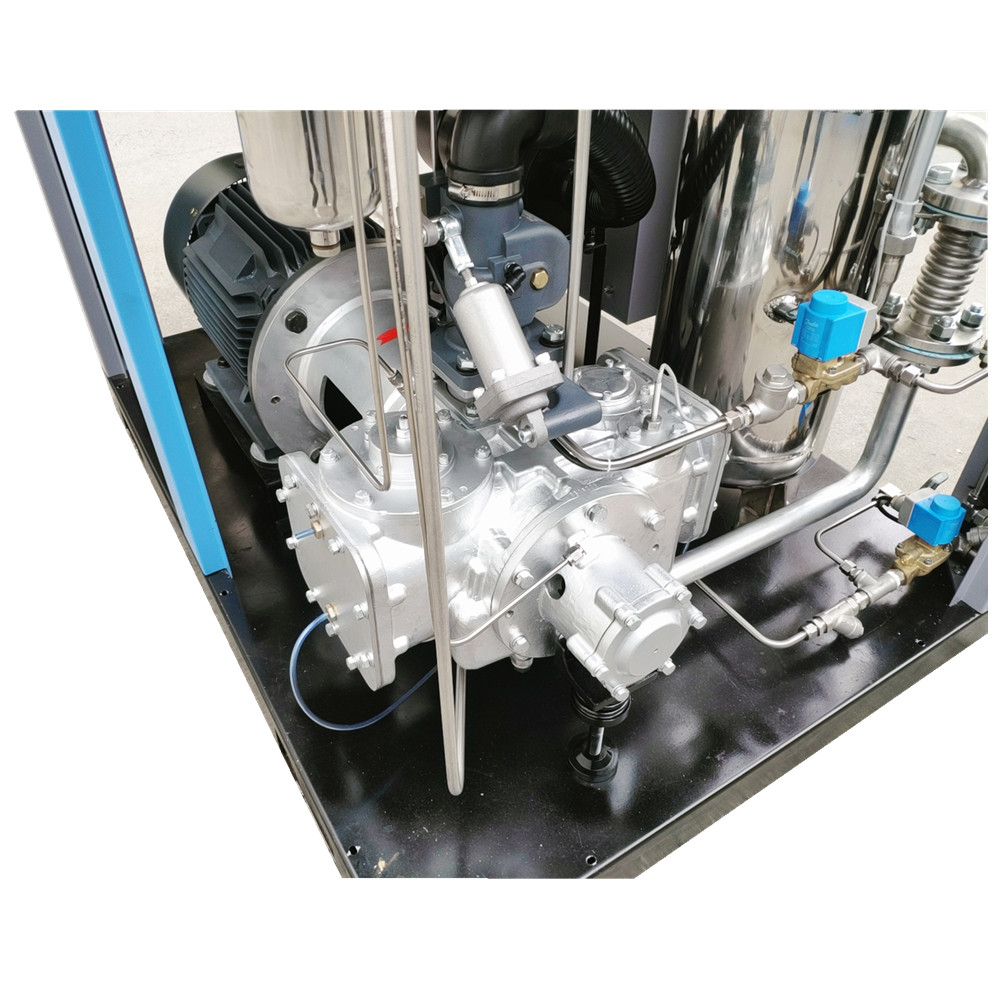

100% oil free compressed air

Features of controller

1, 6” touch screen control panel, user interface for simple and convenient operation.

2, multiple link control available, no link panel required, meeting various demand from customers.

3, power saving/local / remote/auto/manual multiple operating modes.

4, real time alarm and warning display for full control of various conditions.

5, actively power saving and protect design for efficiency power saving and loading control.

6, control system functions.

Status display

Alarm function

System time parameters

System maintenance

Shutdown protection

High efficiency (lubricated water)

Lubricant water functions

Serves as sealant, coolant and lubricant.

Sealing function reduces/seals “blow hole” between rotors and housing to absolute minimum, ensuring efficient compression with delivered air volume per horse power increased by 15% as compared to general dry-type screw units.

Lubricant water also very effectively absorbs and dissipates heat generated during compression process.

High reliability

Oil free screw compressor applies rotary single screw air-end.

By being in market every since 1982, it has undergone practical for over 30 years, all of it’s air quality, power saving and high reliability features have turned out to be state of the art in design and performance.

Air and water are becoming a major trend in compressor market due to their high compatibility, availability, reliability and environment friendliness.

Long interval maintenance periods

Nearly ideal isothermal compression, direct driven method, smart configuration and precision component design and machining, long bearing service life, all of the above essentially extends interval between regular periodical maintenance.

Technical parameters:

| Model | Way of Transmission | Air flow /Pressure | Power | Lubricated water volume | Cooling water volume | Way of Cooling | Speed | Outlet size | Weight | Diemention (mm) | ||||

| m3/min/bar | KW | HP | L/min | L/min | rpm | Kg | L | W | H | |||||

| RMW-10A | Coupling | 1.16/8 | 1.04/10 | 7.5 | 10 | 27 | Air | 2930 | G1'' | 500 | 1300 | 800 | 1300 | |

| RMW-15A | Coupling | 1.56/8 | 1.36/10 | 11 | 15 | 27 | Air | 2930 | G1'' | 540 | 1300 | 800 | 1300 | |

| RMW-20A | Coupling | 2.4/8 | 2.12/10 | 15 | 20 | 27 | Air | 2930 | G1'' | 650 | 1600 | 910 | 1350 | |

| RMW-25A | Coupling | 3.1/8 | 2.62/10 | 18.5 | 25 | 27 | Air | 2940 | G1'' | 840 | 1600 | 910 | 1350 | |

| RMW-30A | Coupling | 3.5/8 | 3.13/10 | 22 | 30 | 27 | Air | 2940 | G1'' | 870 | 1950 | 1050 | 1432 | |

| RMW-40A | Coupling | 5.0/8 | 4.2/10 | 30 | 40 | 40 | Air | 2940 | G1 1/2" | 980 | 1950 | 1050 | 1432 | |

| RMW-50A | Coupling | 6.1/8 | 5.22/10 | 37 | 50 | 40 | Air | 2940 | G1 1/2" | 1000 | 2150 | 1300 | 1590 | |

| RMW-60A | Coupling | 7.3/8 | 6.13/10 | 45 | 60 | 40 | Air | 2960 | G2'' | 1060 | 2150 | 1300 | 1590 | |

| RMW-75A | Coupling | 9.6/8 | 8.6/10 | 55 | 75 | 100 | 150 | Water | 2960 | G2'' | 1250 | 2150 | 1300 | 1590 |

| RMW-100A | Coupling | 12.5/8 | 11.42/10 | 75 | 100 | 100 | 200 | Water | 2960 | G2'' | 1480 | 2150 | 1300 | 1590 |

| RMW-125A | Coupling | 16.3/8 | 14.52/10 | 90 | 125 | 180 | 250 | Water | 2970 | DN80 | 2030 | 2550 | 1400 | 1605 |

| RMW-150A | Coupling | 19.4/8 | 16.9/10 | 110 | 150 | 200 | 270 | Water | 2970 | DN80 | 2450 | 2550 | 1400 | 1605 |

| RMW-175A | Coupling | 22.21/8 | 20.38/10 | 132 | 175 | 240 | 320 | Water | 2970 | DN80 | 2850 | 2550 | 1400 | 1605 |

| RMW-215A | Coupling | 25.0/8 | 24.0/10 | 160 | 215 | 280 | 360 | Water | 2970 | DN100 | 3500 | 2800 | 1850 | 2000 |

| RMW-250A | Coupling | 28.0/8 | 25.0/10 | 185 | 250 | 280 | 360 | Water | 2970 | DN100 | 4000 | 2800 | 1850 | 2000 |

| RMW-270A | Coupling | 33.0/8 | 27.0/10 | 200 | 270 | 320 | 400 | Water | 2970 | DN100 | 4500 | 2800 | 1850 | 2000 |

| RMW-340A | Coupling | 41.0/8 | 38.0/10 | 250 | 340 | 320 | 400 | Water | 2970 | DN100 | 5000 | 2800 | 1850 | 2000 |

Photos: